LOD explains how detailed, accurate, and build-ready your BIM model is at every stage. As the LOD increases, uncertainty drops—giving you clearer coordination, fewer RFIs, faster approvals, reduced rework, and a smoother, more predictable construction process.

Mechanical Services – LOD 100 → Concept (Early Vision)

Meaning: High-level mechanical intent without detailed system definition.

Includes: Conceptual representation of HVAC zones, major equipment footprints, shafts, and service areas based on building massing, orientation, and occupancy assumptions.

Outcome: Rapid feasibility assessments, early cooling/heating demand understanding, preliminary space validation, and informed go/no-go decisions before design commitment.

Critical Insight: Early mechanical clarity prevents oversized systems and late-stage layout failures.

Mechanical Services – LOD 200 → Early Design (Schematic Design)

Meaning: Organized but still flexible mechanical layouts.

Includes: Approximate duct routing, preliminary equipment selection, air distribution concepts, early sizing assumptions, and coordination intent with architectural and structural elements.

Outcome: Clear HVAC design direction, realistic early cost estimates, improved load alignment, and reduced downstream redesign risk.

Critical Insight: Most early HVAC coordination issues are resolved here.

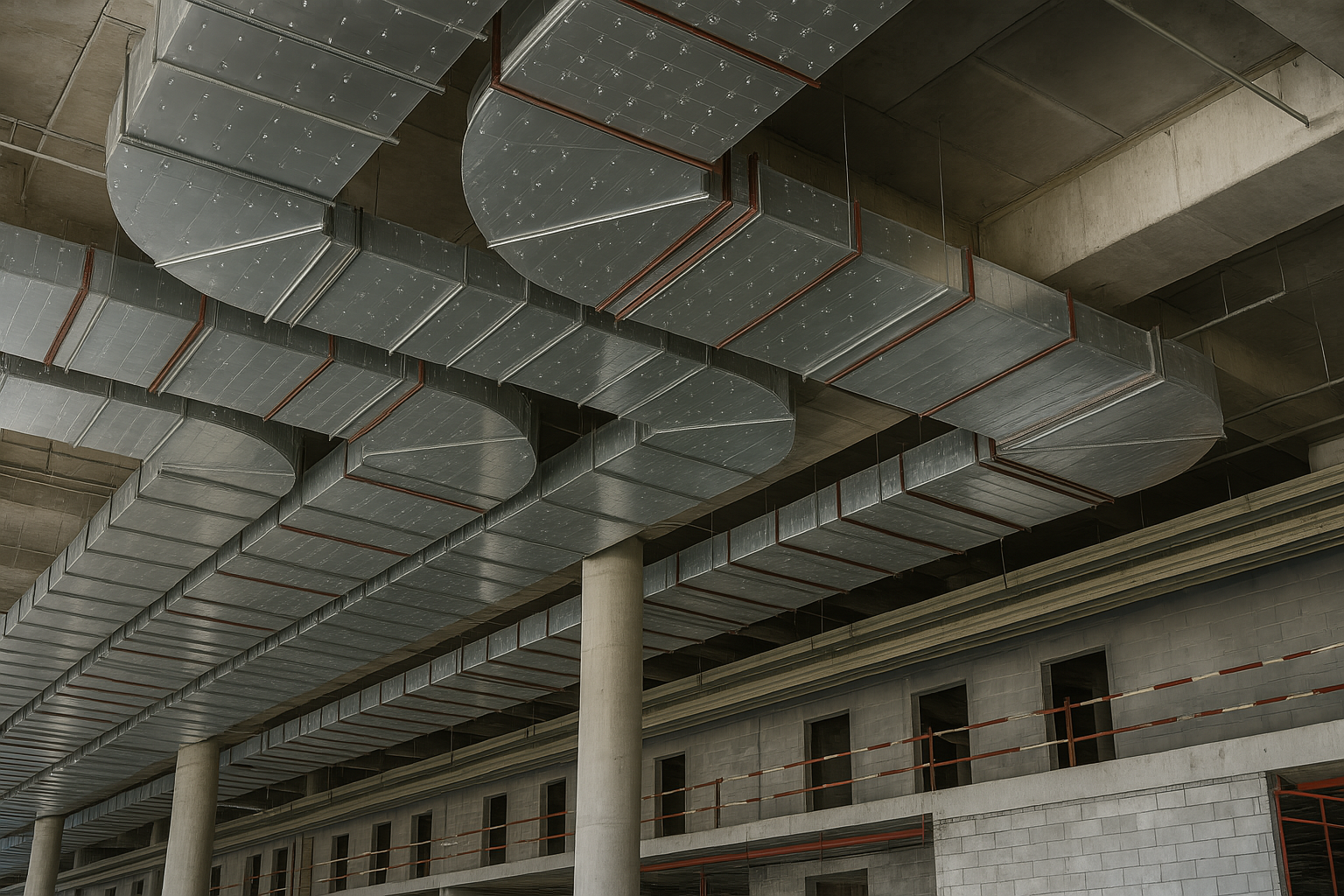

Mechanical Services – LOD 300 → Detailed Design (Accurate & Coordinated)

Meaning: Fully engineered and coordinated mechanical design.

Includes: Accurate duct sizes, precise routing, equipment placement, access and maintenance clearances, coordinated interfaces, and reliable quantity take-offs.

Outcome: Reduced clashes, fewer RFIs, smoother authority approvals, and predictable construction documentation with reduced rework and cost certainty.

Critical Insight: This stage prevents the majority of mechanical site conflicts.

Mechanical Services – LOD 350/400 → Build-Ready (Fabrication Precision)

Meaning: Fabrication- and installation-ready mechanical detail.

Includes: Hangers, supports, insulation details, penetrations, sleeves, vibration control, sequencing clarity, and prefabrication-ready ductwork layouts.

Outcome: Faster shop drawing approvals, minimal site rework, controlled installation, accurate fabrication, and zero execution ambiguity.

Critical Insight: Converts HVAC design intent into field-ready certainty.

Mechanical Services – LOD 500 → As-Built (Verified Digital Twin)

Meaning: Final verified model reflecting actual installed mechanical systems.

Includes: Confirmed as-built duct routing, equipment data, capacities, tags, field modifications, and validated locations matching site conditions.

Outcome: Accurate facilities management, energy optimization, predictable renovations, and long-term asset reliability with reduced lifecycle costs.

Critical Insight: Becomes the owner’s single source of truth for mechanical systems.

This LOD framework ensures complete clarity, predictable coordination, and zero surprises across design, fabrication, and construction — giving every stakeholder the right information at the right time for faster decisions and smoother project delivery.

Get a quick expert review showing exactly where you can prevent rework, shorten timelines, and improve delivery with precision.

Receive a free 1-page project blueprint highlighting coordination risks, approval gaps, and schedule

threats

so delays, rework, and cost overruns are prevented from day one.