Marine Engineering

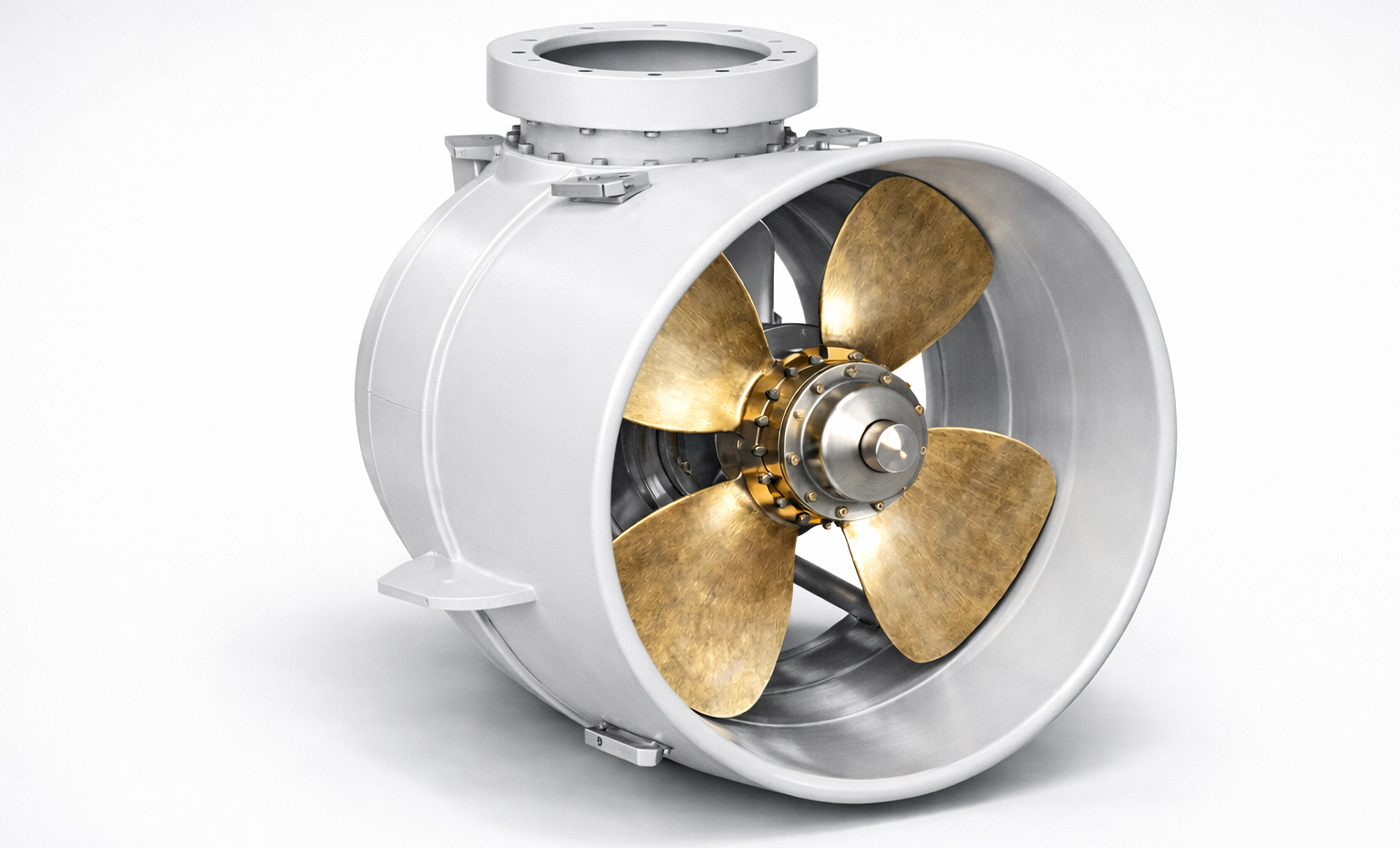

Marine Engineering services deliver accurate production support and constructability

assurance for oil rigs, cargo ships, and marine vessels. They integrate offshore structures,

hull components, piping systems, equipment layouts, and deck modules based on approved

designs. Early coordination and clash checks reduce rework and support safe execution in

harsh environments. The result is seamless collaboration, fabrication-ready outputs, and

standards-compliant, schedule-driven delivery.

Precision

Marine CAD modeling enhances production accuracy and coordination

by creating detailed 3D models. It improves alignment between design

teams and fabrication by translating approved inputs correctly. CAD

reduces errors by identifying clashes and inconsistencies early. It

streamlines the production work flow, minimizing costly rework and

delays. Ultimately, CAD delivers reliable, build-ready outputs that

support faster execution.

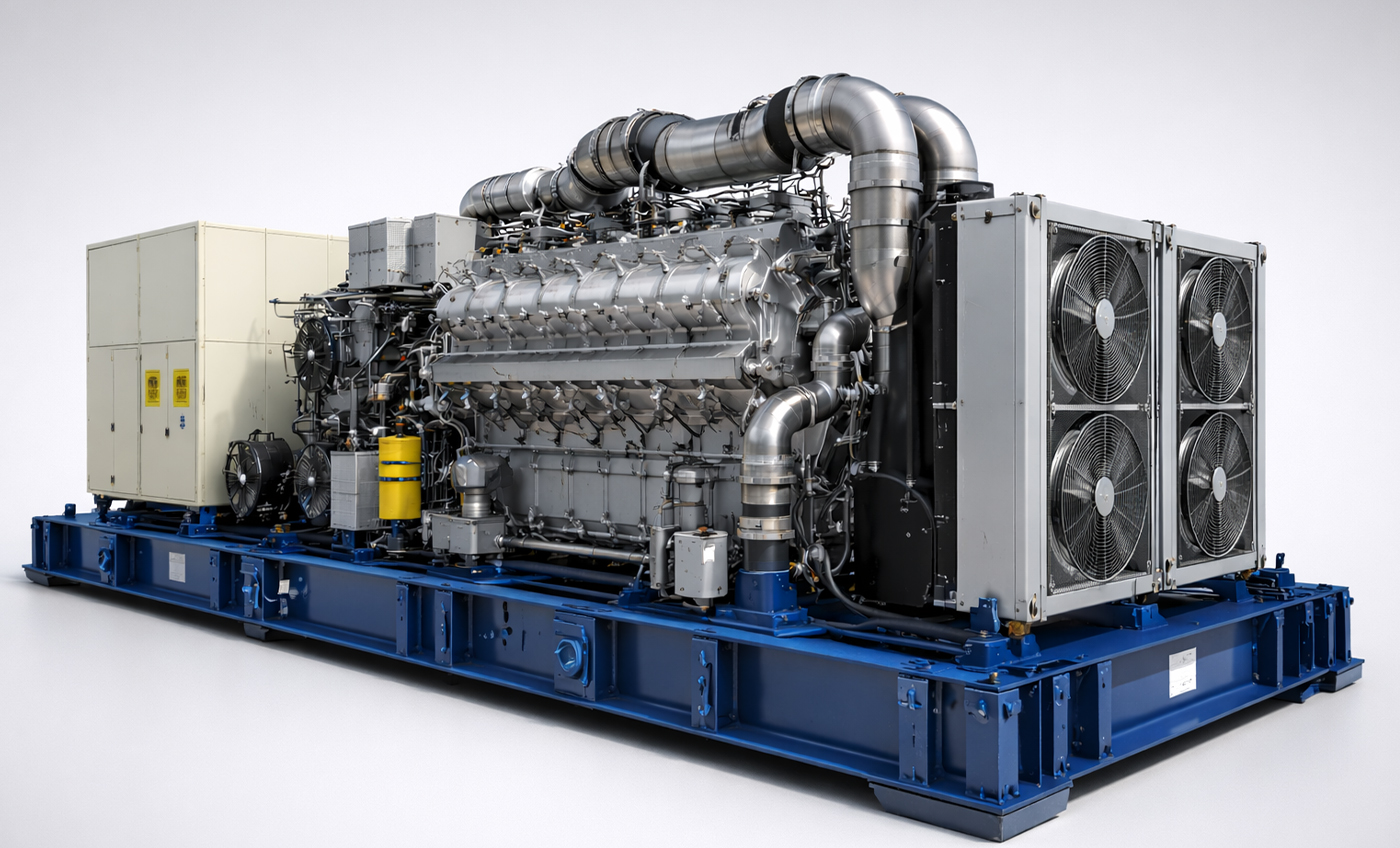

Speed

Marine CAD support accelerates design-to-production cycles by rapidly

converting inputs into usable models. It improves delivery timelines by

supporting continuous progress across time zones. Faster modeling

reduces bottlenecks during reviews and fabrication planning. This

approach streamlines workflows, minimizing idle time and schedule

overruns. Ultimately, faster CAD delivery keeps marine projects on

track.

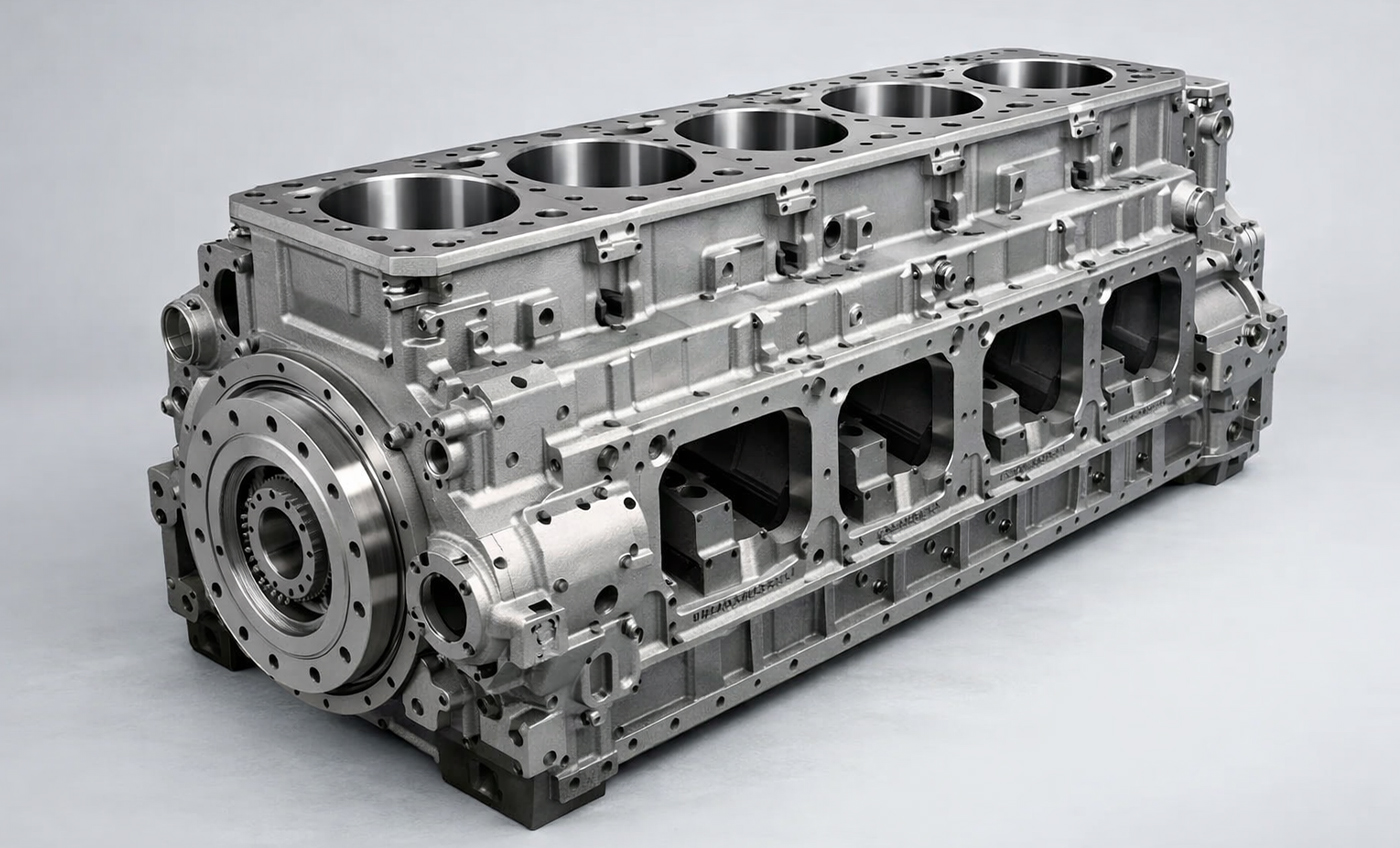

Buildability

Production-focused CAD modeling improves constructability by

reflecting real fabrication conditions. It aligns models with yard

constraints, tolerances, and installation sequences. Build-aware

modeling reduces shop-floor confusion and on-site adjustments. This

approach streamlines fabrication and assembly, minimizing disruptions

during execution. Ultimately, buildable models ensure smoother

production and installation outcomes.

Compliance

Standards-driven CAD modeling improves consistency by following

client and class requirements. It aligns deliverables with approved layer

structures, naming conventions, and formats. Compliance-focused

modeling reduces review comments and revision cycles. This

consistency streamlines approvals, minimizing delays and coordination

issues. Ultimately, compliant outputs support audit-ready and

approval-friendly delivery.

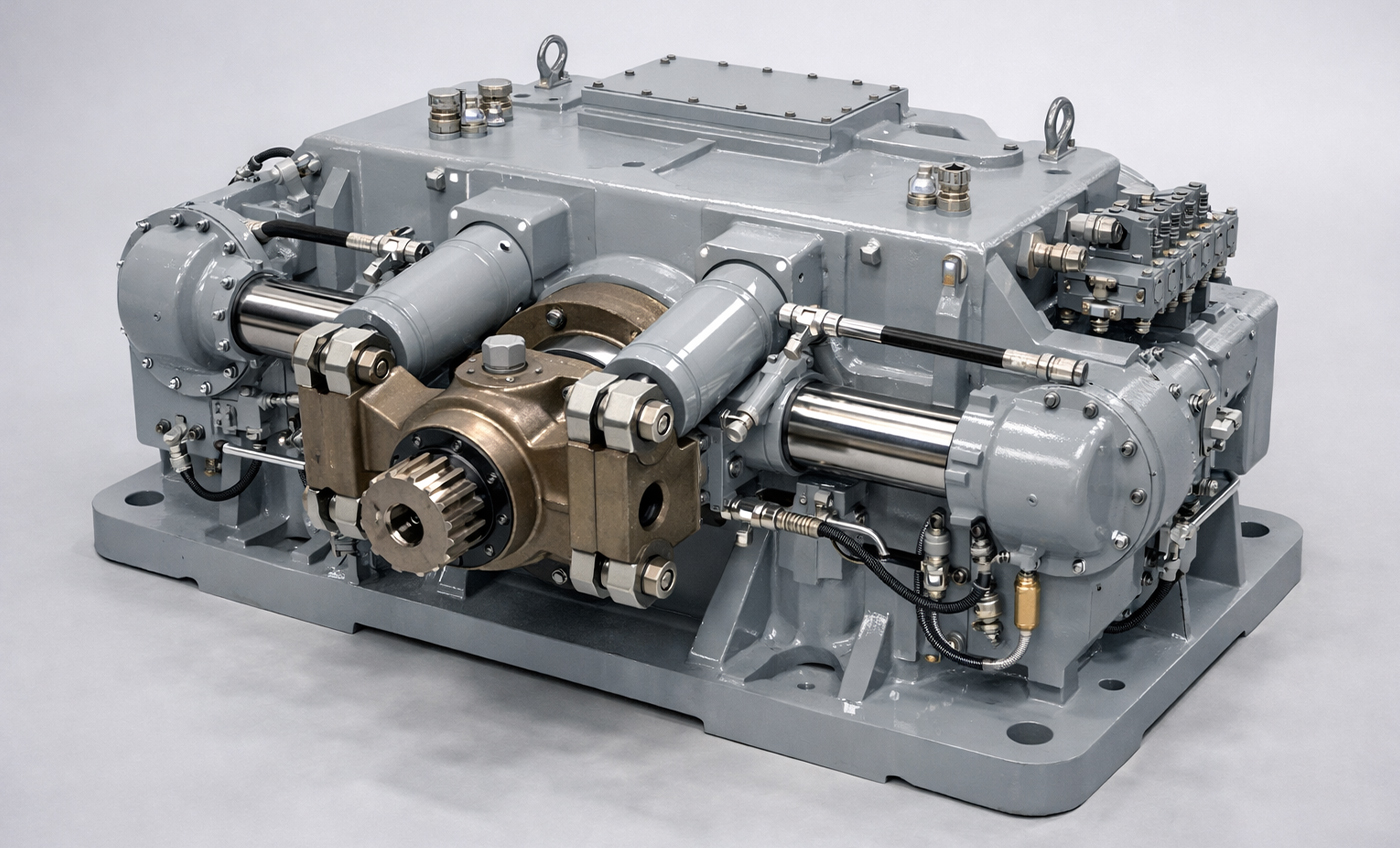

Scalability

Scalable marine CAD support improves capacity by extending in-house

teams on demand. It enables clients to handle peak workloads without

long-term hiring commitments. Flexible resourcing reduces operational

strain during high-volume project phases. This model streamlines

capacity planning, minimizing overhead and resource risk. Ultimately,

scalable CAD support enables stable growth and predictable delivery

Frequently Asked Questions

+ What do you do in marine projects?

We provide marine CAD and 3D modeling support that converts approved designs into accurate,

production-ready deliverables.

+ Do you design ships?

No. We do not perform ship design or naval architecture. We support your design teams by developing CAD

models strictly from your inputs.

+ How does this help my project?

It reduces rework, RFIs, and delays, helping fabrication and installation start faster and run smoother.

+ Who typically works with you?

Shipyards, offshore EPCs, marine contractors, fabricators, and marine equipment manufacturers.

+ Can you follow our CAD standards?

Yes. We strictly follow your CAD standards, templates, layer structures, and workflows.

+ How fast can you deliver?

Our global delivery model enables 30–40% faster design-to-production turnaround on most projects.

+ How do you ensure quality?

Every deliverable goes through structured QA/QC checks focused on accuracy, coordination, and

buildability.

+ Can you scale with our workload?

Yes. We provide on-demand marine CAD capacity that scales up or down without hiring risk.

+ How do you work with our internal teams?

We work as an extension of your in-house team, aligning with your review cycles and communication tools.

+ What is the main benefit of working with you?

You gain faster delivery, fewer errors, and flexible production capacity without increasing overhead.