Reverse Engineering

Reverse Engineering services enable precise digital reconstruction of physical components, ensuring

accurate design modifications and seamless CAD integration. By capturing detailed measurements through

3D scanning, it facilitates part replication, legacy component restoration, and product optimization

with minimal errors. This process enhances operational efficiency, reduces development costs, and

accelerates innovation through improved analyzes, customization, and rapid prototyping.

Reconstruction

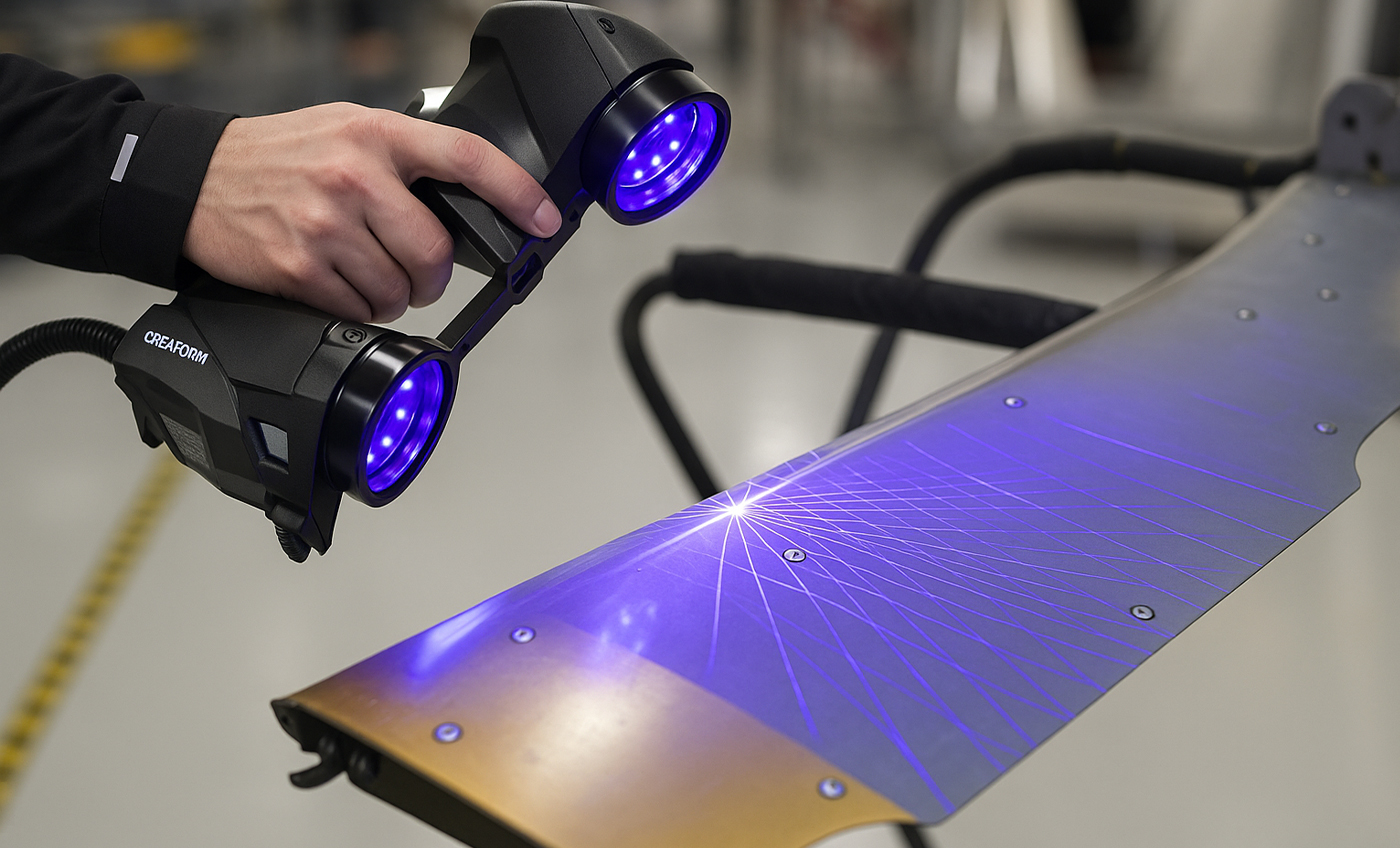

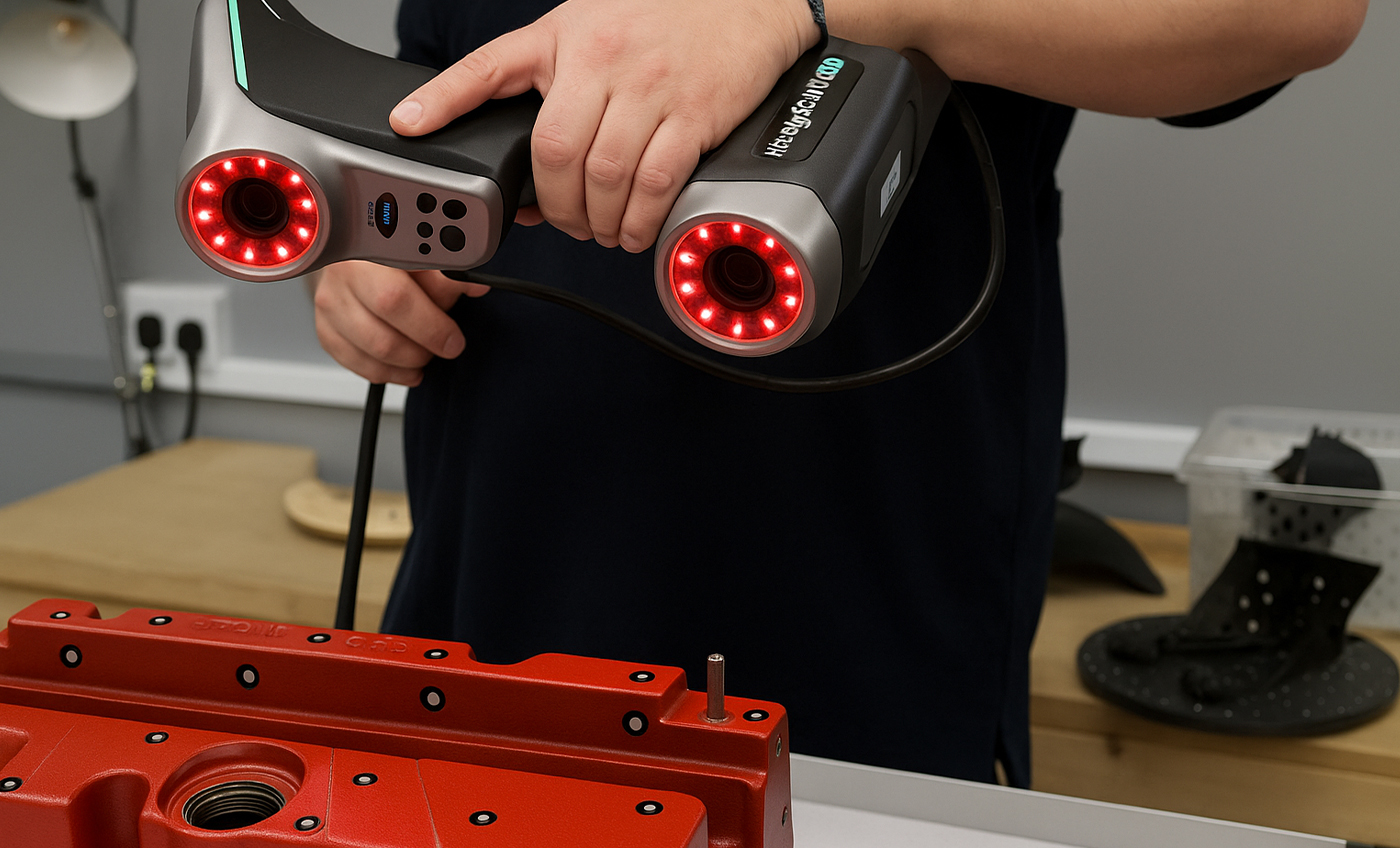

We use advanced scanning technologies, like 3D laser scanning and photogrammetry, to capture precise

details of physical objects. This allows us to create accurate 3D CAD models that form a solid

foundation for product development, prototyping, and manufacturing. Whether handling complex geometries

or intricate parts, our reverse engineering ensures the models reflect real-world specifications,

streamlining both the design and production process.

Optimization

Our team analyzes reverse-engineered models to uncover areas for improvement, such as structural

flaws, high production costs, or material inefficiencies. We then propose design modifications that

enhance functionality, durability, and performance, while also cutting down on waste and material

costs. This improves product lifespan, boosts performance, and helps keep your product competitive

in the market while reducing manufacturing costs.

Cost-Effective

By converting physical prototypes or legacy designs into digital 3D models, we eliminate the need

for expensive re-engineering from scratch. This approach saves both time and money, especially when

redesigning obsolete or discontinued parts. Our Reverse CAD Engineering services support fast

iteration, rapid prototyping, and testing, speeding up the product development cycle while ensuring

cost-efficiency in manufacturing.

Integration

Our reverse-engineered 3D models are fully compatible with top CAD software platforms like AutoCAD,

SolidWorks, and CATIA. This ensures easy integration into your design and production processes.

Whether you're updating a product, performing machinery maintenance, or incorporating

reverse-engineered parts into larger systems, our models ensure a smooth transition, reducing both

time and complexity during design integration.

Documentation

Along with detailed CAD models, we provide full documentation to support your engineering and

manufacturing teams. This includes 2D drawings, technical specifications, and material analysis,

ensuring clear communication at every stage of production. Our thorough reports make it easy for

both your team and external partners to understand the design elements, enabling smooth

collaboration and efficient project execution.

Frequently Asked Questions

+ What is Reverse

Engineering?

Reverse engineering analyzes

and recreates existing parts, products, or structures into accurate digital 3D CAD models.

+ How does Reverse

Engineering work?

We use 3D scanning, software

processing, and CAD modeling to digitally reconstruct components for design, manufacturing, or

analysis.

+ What industries benefit

from Reverse Engineering?

Automotive, aerospace,

manufacturing, medical, and industrial sectors use it for part replication, design improvements, and

innovation.

+ What file formats do

you provide?

We deliver 3D CAD models in

STEP, IGES, STL, and native formats like SolidWorks, CATIA, or NX based on your requirements.

+ What are the benefits of Reverse Engineering?

It helps in part

reproduction, legacy part restoration, design optimization, failure analysis, and competitive

benchmarking.

+ How long does the Reverse Engineering process

take?

Project duration varies based

on complexity, but most scans and models are completed within a few days to a few weeks.

+ Can you reverse engineer worn or broken

parts?

Yes, we reconstruct worn or

damaged parts by digitally restoring their original shape for manufacturing or modification.

+ Do you offer modifications or design

improvements?

Yes, we refine existing

designs by optimizing dimensions, materials, or features for better performance and efficiency.

+ What is the cost of Reverse Engineering

services?

Pricing depends on part

complexity, size, and required accuracy—contact us for a detailed quote based on your project.

+ How do I get started with your Reverse

Engineering services?

Send us your part details,

and we’ll guide you through scanning, modeling, and delivering the final CAD design.