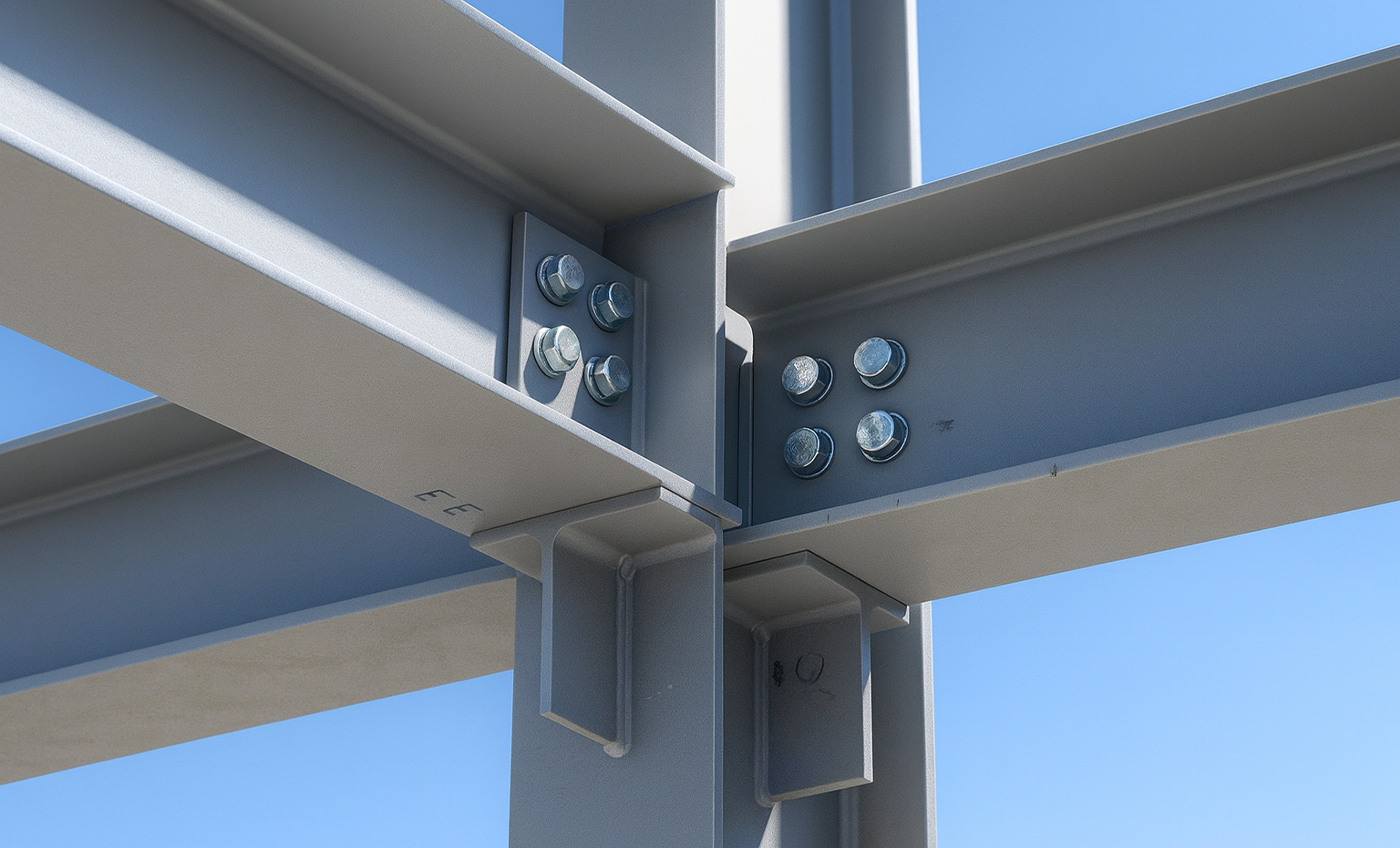

Steel Connection Design

Structural steel connection design ensures secure joints between steel members for effective load

transfer and stability. Bolted and welded connections must withstand various forces while complying with

building codes and standards. Well-designed connections enhance structural strength, optimize

construction efficiency, and improve cost-effectiveness. Additionally, they provide flexibility in

architectural design while minimizing the risk of failure, contributing to the longevity and performance

of steel structures.

Codes & Standards

Our connection designs are carefully developed to surpass industry standards, including AISC,

Eurocode, and local

seismic codes. This guarantees that each connection is not only safe and durable but also fully

compliant with

all legal and regulatory requirements. We are dedicated to staying informed on the latest updates to

relevant

codes and standards, ensuring our solutions are innovative, reliable, and deliver optimal

performance.

Precision Engineering

Our expert team is dedicated to designing structural steel connections with precise accuracy,

ensuring effective load transfer

and lasting strength. Using advanced modeling and simulation tools, we thoroughly assess the

performance of each connection under

varying load conditions. This meticulous process results in robust connections that can endure both

static and dynamic forces, while

optimizing material use to minimize waste and cut costs.

Tailored Solutions

We understand that each project presents its own unique challenges, which is why we provide

customized connection designs

that meet the specific requirements of your structure. Whether for industrial facilities, high-rise

buildings, or bridges,

our designs are engineered to deliver maximum efficiency, meet performance goals, and address

constraints such as space

limitations or load-bearing needs, all while keeping costs in check.

Efficient Integration

We prioritize seamless integration between our structural steel connections and the rest of your

project. By working closely with

architects, engineers, and contractors, we ensure that our designs align perfectly with the overall

structure. This collaborative

approach reduces potential construction delays, eliminates conflicts, and guarantees that all

components beam, columns, and braces

fit together precisely for maximum performance and efficiency.

Software & Tools

To ensure the highest accuracy and efficiency, we use leading-edge design tools like AutoCAD, Revit,

and specialized connection

design software such as RAM Connection and Tekla Structures. These tools allow us to create detailed

3D models, optimizing connection

designs for both structural integrity and cost-effectiveness. Our use of advanced technology also

results in highly precise fabrication

drawings, minimizing errors during production and installation.

Frequently Asked Questions

+ What is Steel

Connection Design?

Steel Connection Design

involves engineering safe, efficient, and code-compliant joints between steel structural elements.

+ Why is Steel Connection

Design important?

Proper design ensures

structural stability, load transfer, and compliance with safety standards, preventing failures and

inefficiencies.

+ What types of steel

connections do you design?

We design bolted, welded,

moment, shear, braced, and custom connections based on structural and project requirements.

+ What codes and

standards do you follow?

We comply with AISC,

Eurocode, BS, IS, and other relevant international and regional steel design standards.

+ What software do you

use for connection design?

We utilize Tekla, SDS/2,

STAAD Pro, and other advanced tools to ensure precise and optimized designs.

+ Do you provide steel

connection design support and detailing for fabrication?

Yes. We provide connection

design support and detailed drawings based on engineer-provided criteria for fabrication and

coordination.

+ What industries benefit

from your services?

Our designs support

construction, industrial, commercial, and infrastructure projects needing efficient steel connections.

+ How long does the

design process take?

Timelines vary based on

project size and complexity, typically ranging from a few days to a couple of weeks.

+ What information do you

need to start a project?

We require structural

drawings, load details, material specifications, and any project-specific requirements.

+ How do I get a quote

for steel connection design?

Contact us with project

details, and we’ll provide a customized proposal based on scope, complexity, and deadlines.