Structural Steel Detailing

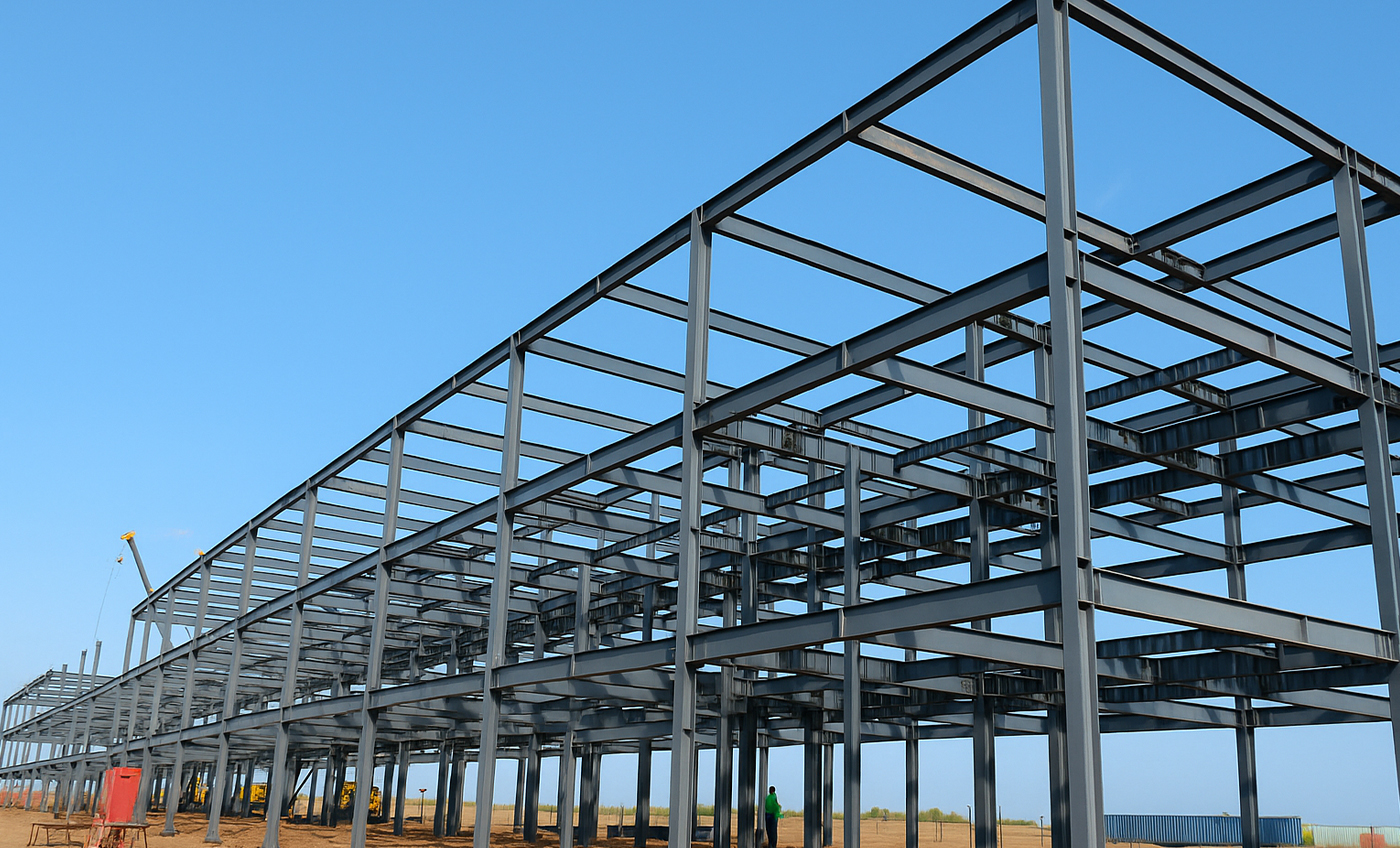

Structural Steel Detailing is the process of creating accurate, detailed drawings and 3D models for the

fabrication and erection of steel structures. It converts design intent into precise, construction-ready

plans, including dimensions, materials, connections, bolts, and welds. Quality detailing ensures

clash-free construction, improves coordination, reduces costly errors, and significantly boosts overall

project efficiency. It is essential for buildings, bridges, industrial plants, and other large-scale,

steel-based infrastructure projects.

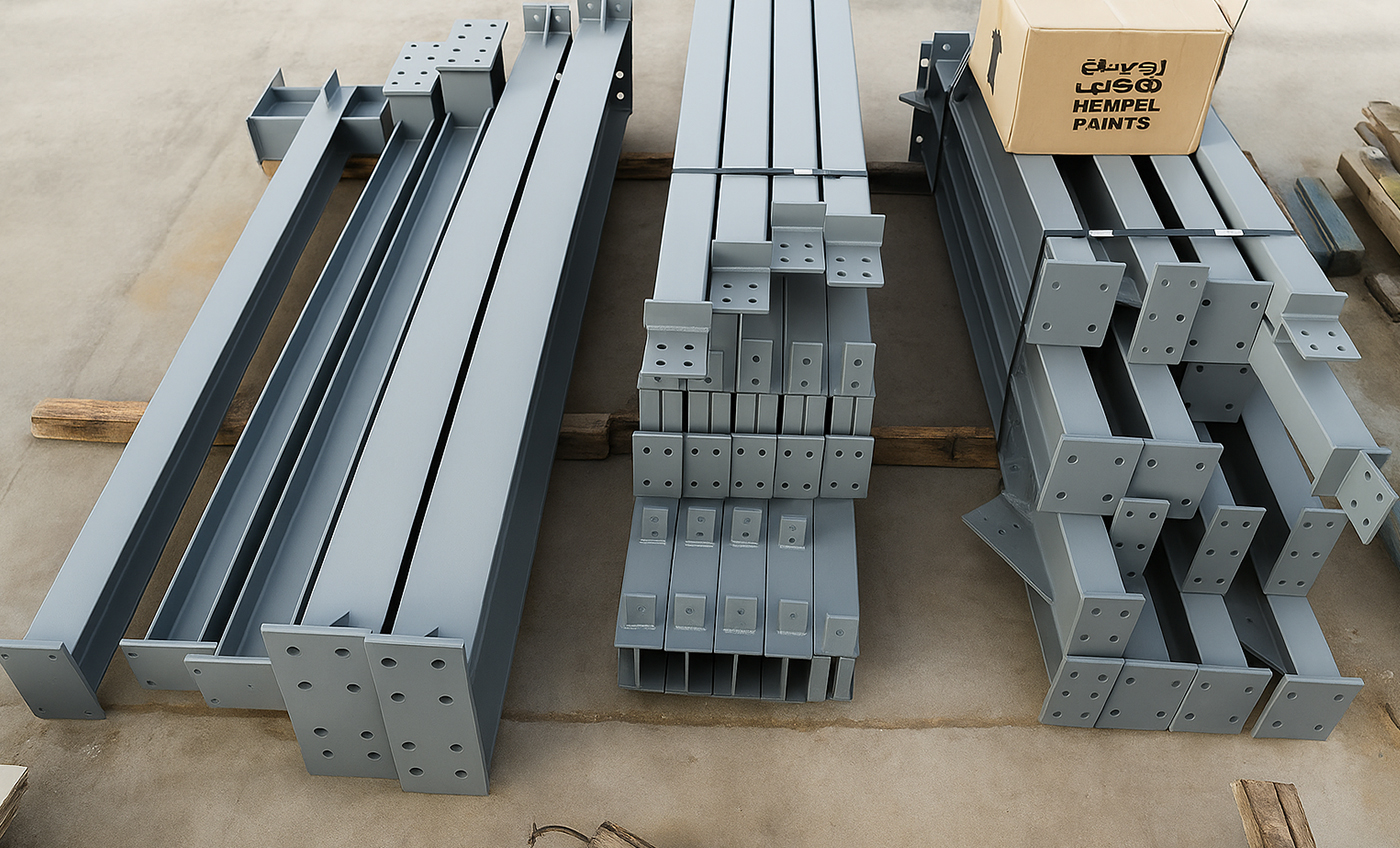

Shop Drawings

Our structural shop drawings provide essential specifications for fabrication, including steel profiles,

connection details, welding, bolting, and material specs. These accurate drawings streamline fabrication

by eliminating uncertainties, minimizing errors, and ensuring coordination between teams. This ensures

components fit perfectly on-site, reducing mistakes, delays, and rework, while improving project

efficiency and on-time delivery.

3D modeling

Our 3D modeling services using Tekla, SDS2, and Advance Steel ensure highly accurate and detailed

representation of every structural steel component. These advanced tools precisely define dimensions,

connections, and tolerances, greatly minimizing discrepancies between design and fabrication. This level

of precision reduces errors, optimizes material usage, and enhances overall efficiency, ensuring faster,

with minimal rework and fewer delays.

Constructability

By leveraging advanced 3D models, we identify and resolve clashes between steel elements and other

building systems early in the design phase. This proactive clash detection ensures all components

are fabricated to precise specifications, minimizing costly adjustments and avoiding delays. It

leads to smoother on-site assembly, reducing errors, rework, and saving valuable time, resources,

and costs throughout the project lifecycle.

Collaborative

The integration of Tekla, SDS2, and Advance Steel enhances collaboration between project teams,

fabricators, and contractors, creating a unified workflow. Real-time updates, shared models, and

advanced clash detection enable smooth synchronization of design changes, preventing delays. This

results in better-coordinated fabrication, quicker decision-making, and faster project delivery,

ensuring the project stays on schedule and within budget.

Project Delivery

With Tekla, SDS2, and Advance Steel, we guarantee that all structural steel components are modeled,

fabricated, and delivered on time and according to detailed specifications. These advanced tools

ensure accurate fabrication, efficient material handling, and timely delivery of components in the

correct sequence. This streamlines the construction process, reduces delays, and guarantees that the

project stays on track for timely completion.

Frequently Asked Questions

+ What are structural

steel fabrication drawings?

These detailed technical

drawings, including shop, assembly, and erection plans, guide the manufacturing and installation of

steel structures.

+ Why are fabrication

drawings important?

They ensure accurate

dimensions, material specifications, and connection details, reducing errors, minimizing waste, and

improving assembly efficiency.

+ Do you provide 2D and

3D fabrication drawings?

Yes, we offer 2D shop

drawings for fabrication, 3D steel detailing for visualization, and BIM coordination drawings to prevent

clashes.

+ What software do you

use for steel fabrication drawings?

We use Tekla Structures,

AutoCAD, Advance Steel, Revit, SolidWorks, and SDS/2 to create precise and fabrication-ready drawings.

+ Can you create fabrication drawings from

design sketches?

Yes, we convert hand

sketches, PDFs, and CAD models into detailed fabrication drawings optimized for manufacturing.

+ Do you provide connection details in your

drawings?

Absolutely! Our drawings

include weld symbols, bolt placements, plate sizes, bracing details, and structural connections per

standards.

+ What file formats do you deliver for

fabrication drawings?

We provide DWG, DXF, PDF,

IFC, and NC files, ensuring compatibility with CNC machines and fabrication workflows.

+ Can you modify or update existing steel

drawings?

Yes, we refine, correct, and

update existing drawings to align with design revisions and project requirements.

+ What industries do you serve with fabrication

drawings?

We support construction,

industrial plants, commercial buildings, warehouses, bridges, and infrastructure projects.

+ How can I request a quote for steel

fabrication drawings?

Share your project details,

material specs, and timeline via email or our website for a customized quote.